What is process validation?

Process validation is where facilities require assurance that a process, such as sterilization or depyrogenation, has been performed to a certain standard. For example, facilities that sterilize products must validate that a high enough temperature is reached in order for sterilization to occur. This certifies that the product is completely safe, high quality and meets regulatory compliance.

Process validation often relates to validating temperature, including both air and product temperature. Temperature data loggers are essential for successfully validating a process in your facility. This is because they can provide you with precise time stamps of the exact temperatures reached during a process. Thus, this allows you to comply with industry regulations and offer safe products to the market.

What industries use temperature data loggers for thermal process validation?

Thermal process validation is particularly popular within the pharmaceutical industry but is also often used within manufacturing to facilitate quality control.

Processes such as depyrogenation (removing pyrogens/toxins from a substance), dry heat sterilization and lyophilization (freeze drying) are often undergone within pharmaceutical facilities. These processes bring bacteria down to a safe level and can even increase shelf life of products such as drugs and vaccines. Sterilization and lyophilization data loggers can guarantee that these processes are undergone safely.

What regulations do process validation data loggers help meet?

When facilities use data loggers for process validation, they have sufficient evidence to prove regulatory compliance. The main compliance that our data loggers help to meet is set by the FDA (Food and Drug Association). They have a set of guidelines that facilities should follow to certify they are operating safely. Our temperature data loggers are equipped with FDA 21 CFR Part 11 compliant software help you meet government regulations.

Loggershop’s data loggers for temperature validation

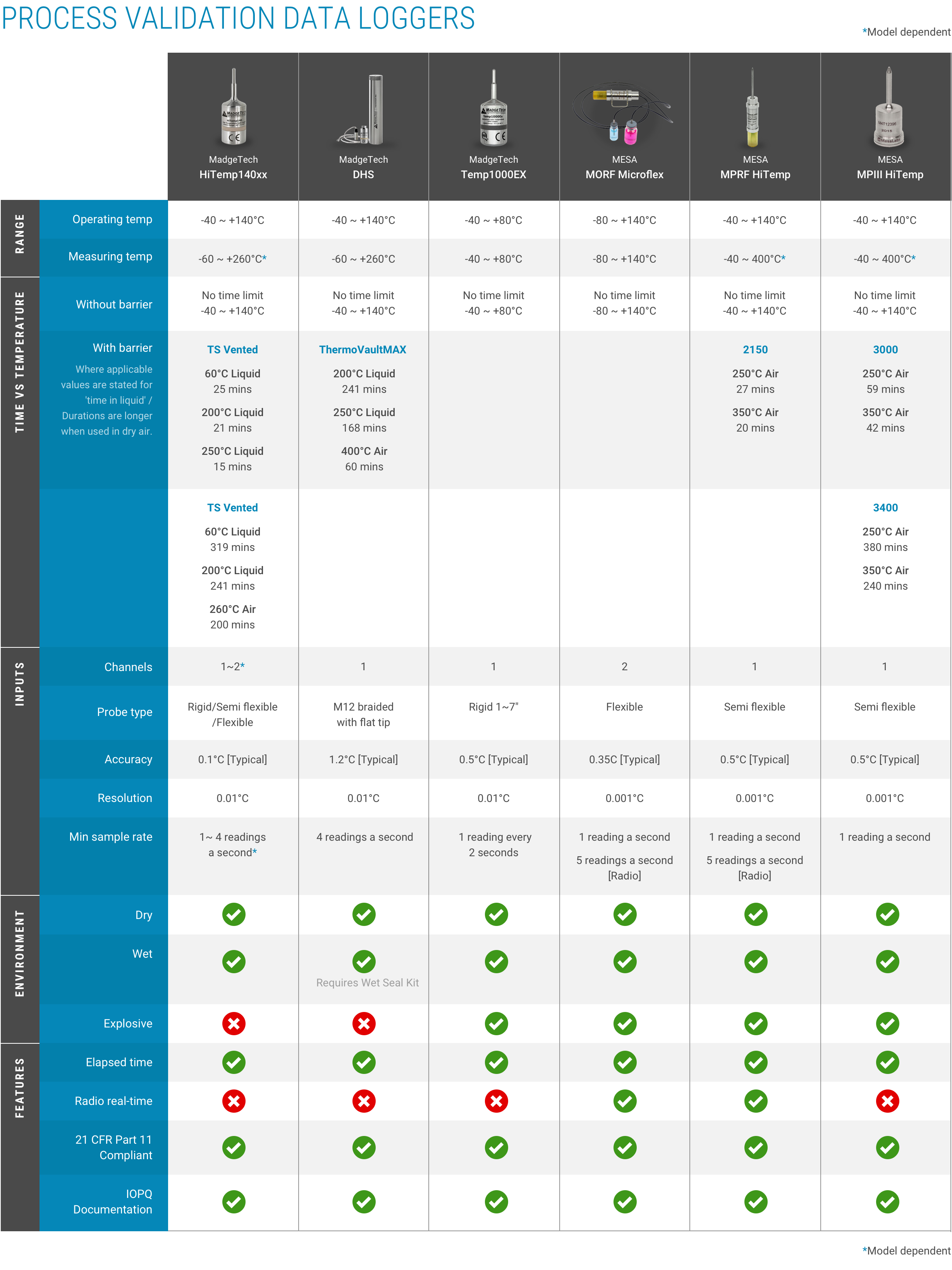

We stock a range of industry trusted data loggers to help you achieve temperature validation, including air temperature sensors, temperature data loggers with probes and more. Browse the table below to learn more about the individual characteristics of each data logger, helping you to find the perfect solution.

For more information about process validation and further advice about selecting a data logger, get in touch with our team of experts at Loggershop. Call 01929 459459 or email [email protected] today.