What are explosion proof temperature and humidity sensors used for?

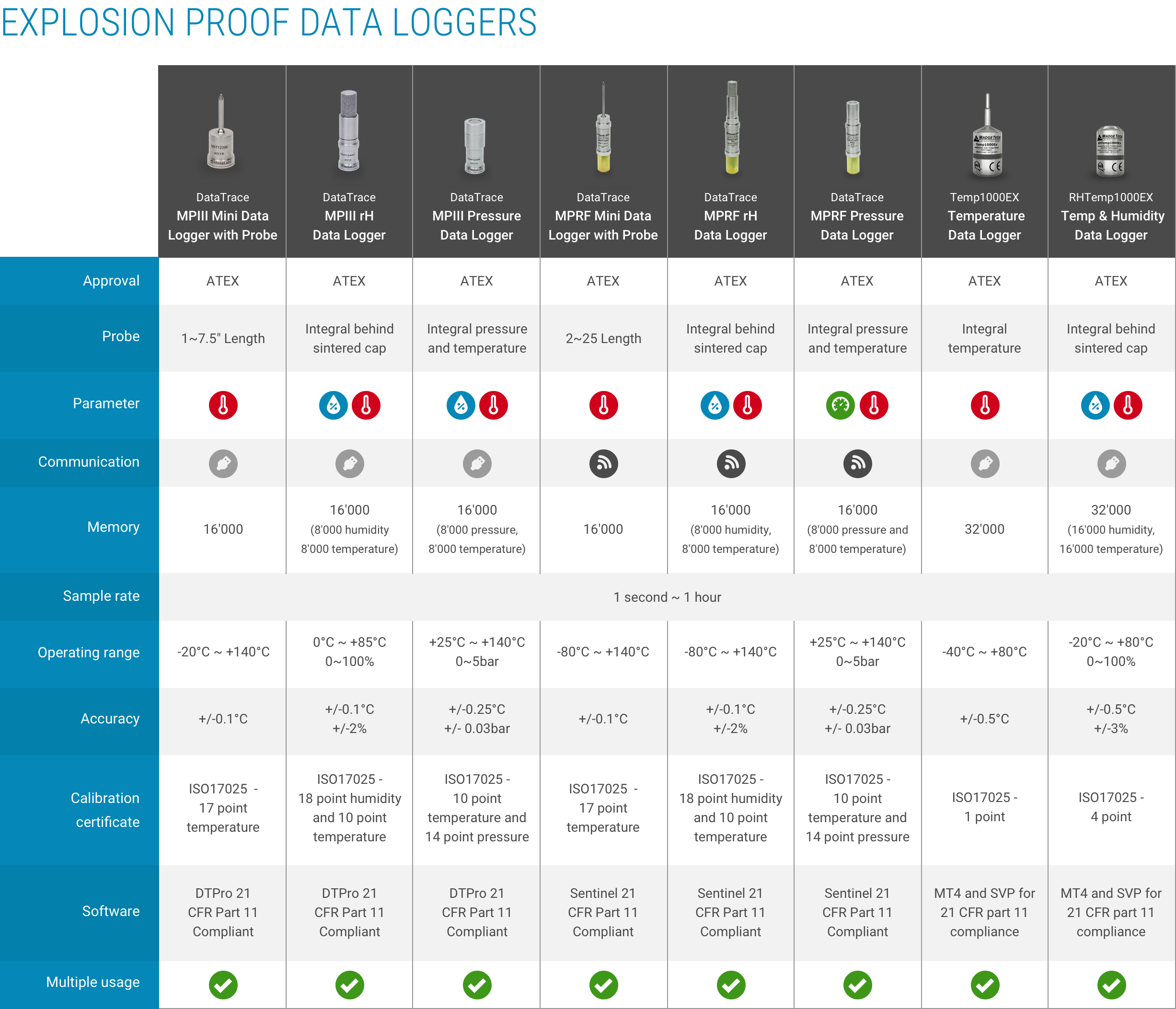

Explosion proof data loggers are designed for use in harsh environments, including ETO settings and in extreme temperature. The application determines which intrinsically safe data logger is required.

There are two types of intrinsically safe data loggers:

- Ethylene oxide validation data loggers

In the past we’ve been asked ‘can I get explosion proof data loggers?’, and you can, but it must be certified for this extreme use. Ethylene oxide validation data loggers are built for use in harsh conditions, such as long-term placement in ETO environments. Explosion proof data loggers continuously deliver reliable and accurate data, and they are GMP and 21 CFR Part 11 compliant.

- Extreme temperature data logger

Data loggers under this classification are suitable for use as submersible data loggers, able to collect data whilst under water. These intrinsically safe data loggers also work when placed in extreme temperatures, such as flammable stores.

Which harsh environments are explosion proof data loggers suitable for?

All data loggers verified as intrinsically safe are certified for use within harsh environments in the below industries:

- Biotech

- Mining

- Oil

- Gas

Follow our guide below to choosing explosion proof humidity sensors for your application. Intrinsically safe data can be collected and validated by an external service such as Wessex Power, ideal for larger projects and to save time. If you would like to discuss your project with one of our expert team before purchasing intrinsically safe data loggers, call us on 01929 459 459.