Accurate vaccine supply chain management is now more important than ever to ensure vaccines are stored and transported safely at the correct temperature. This can be achieved through the deployment of temperature data loggers throughout every stage of your supply chain. From cold chain vaccine storage to -80°C transportation, Loggershop stock a range of industry leading vaccine data loggers. Read our guide to find out more and which data logger is best suited to your facility:

What is a vaccine data logger?

A vaccine data logger is used for monitoring the temperature or humidity of a vaccine during every stage of the supply chain, including storage and transportation. Temperature data loggers can be programmed to notify supply chain managers if a vaccine enters an undesired temperature zone. This helps facilities to certify that they are working with safe temperatures and comply with government guidelines.

Why is vaccine temperature monitoring important?

In order to be safe and effective for use, vaccines must be stored and transported at ultra-low temperatures in medical grade fridges and freezers. If an environment is not kept at a suitable temperature, vaccines can become compromised and are therefore not fit for use. The ongoing COVID-19 pandemic has also created an immeasurable need for effective cold chain vaccine storage and transportation. If vaccines become compromised during trials or after its initial release then product and cost wastage will increase, as the vaccines can no longer be administered to humans. Furthermore, this will create delays in the distribution process compounding the detrimental effect on public health.

Without vaccine data loggers, pharmaceutical companies and supply chain managers would have no sufficient evidence that vaccines are safe to use. Temperature data loggers ensure that vaccines are stored at the correct temperature, whilst providing real-time visibility of the vaccine’s temperature at each stage of the cold chain. This helps to resolve any issues as they arise and before vaccines become ineffective and unsafe for human administration.

What vaccine data loggers do we offer?

Loggershop stock a range of vaccine fridge and freezer data loggers suitable for a wide variety of challenges to help manage the cold chain at each stage.

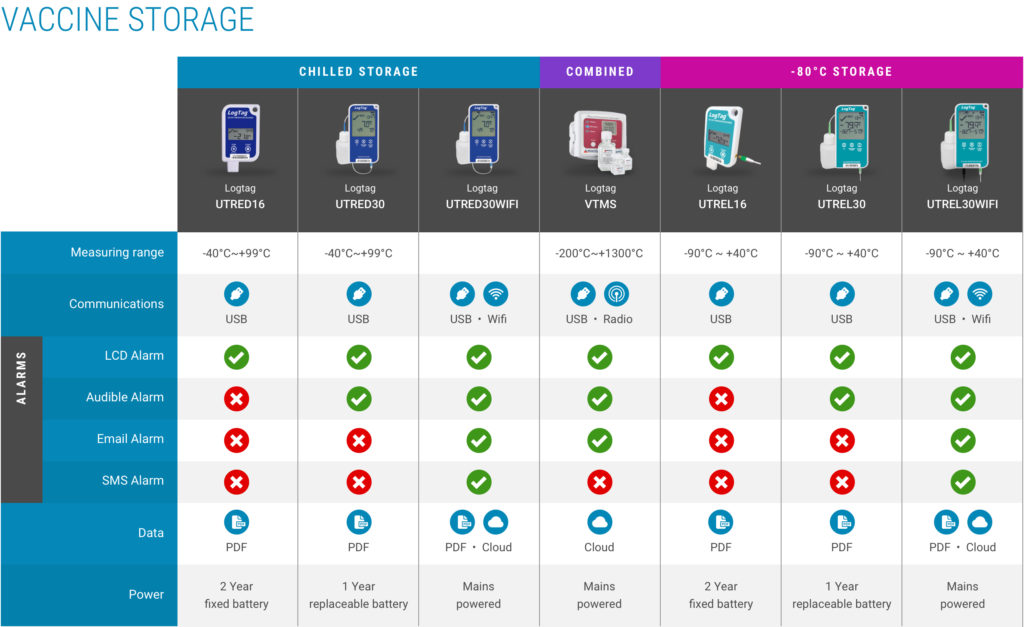

- -20°C Chilled Storage: These vaccine data loggers are suitable for use in -20°C freezers and +2°C to +8°C fridges during cold chain vaccine storage.

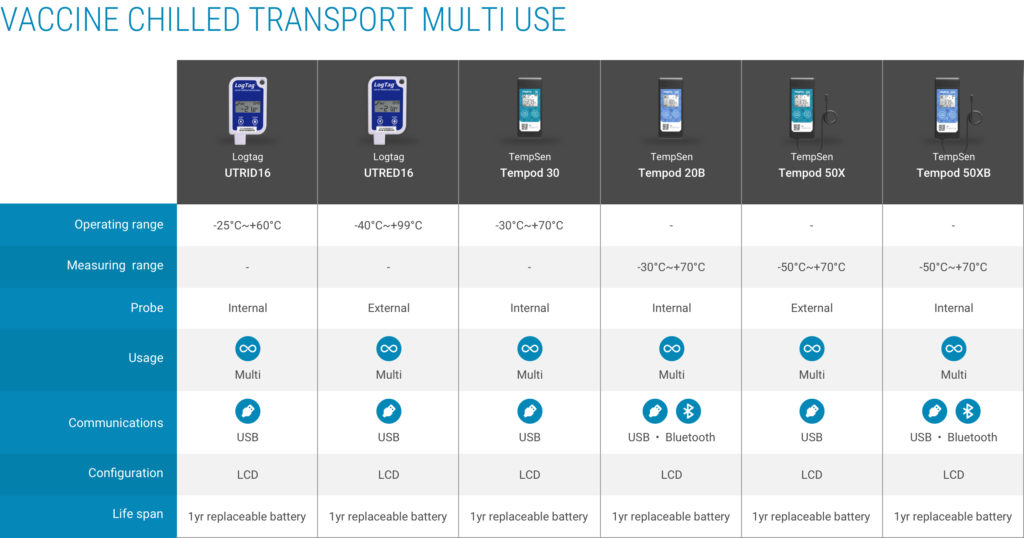

- –20°C Chilled Transport (Multi Use): Our multi use temperature data loggers for vaccines are ideal for transportation in -20°C and 2-8°C environments. Incredibly versatile, they can be used more than once and are available with external and internal probes.

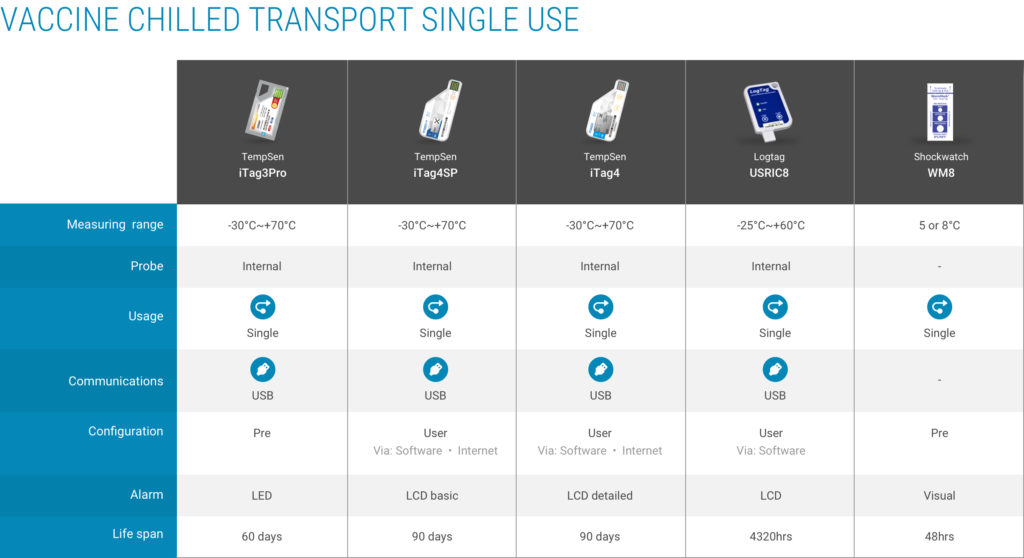

- -20°C Chilled Transport (Single Use): Use our single use vaccine data loggers for quick and easy temperature monitoring in -20°C and +2°C to +8°C shipping environments.

- -80°C Storage: If you are storing vaccines in ultra-low freezers before reaching vaccination centres, our -80°C temperature data loggers ensure vaccines remain in optimal conditions.

- -80°C Transport: Our -80°C vaccine transportation data loggers are designed to cope in extremely low temperature environments, ideal for shipping vaccines in dry ice packs.

- Vaccine Storage Validation: Achieve process validation of your vaccine transportation packing and storage appliances with our validation data loggers.

What compliance do vaccine data loggers help to meet?

When shipping and storing vaccines, supply chain managers must comply with WHO guidelines whereby different packaging have different temperature requirements. This can be achieved through deployment of temperature data loggers that provide precise temperature measurements during both storage and shipping. The guidelines are as follows:

Class A packaging – Highly heat sensitive and not freeze sensitive

The warmest temperature inside the insulated vaccine package must not rise above +8°C in continuous outside temperatures of +43°C for a minimum of 48 hours.

Class B packaging – Heat sensitive and not freeze sensitive

The warmest temperature inside the insulated vaccine package must not rise above +30°C in continuous outside temperatures of +43°C for a minimum of 48 hours.

Class C packaging – Heat sensitive and freeze sensitive

The warmest temperature inside the insulated vaccine package must not rise above +30°C in continuous outside temperatures of +43°C for a minimum of 48 hours. The coolest temperature inside the insulated vaccine package must not fall below +2°C in continuous external temperatures of -5°C for 48 hours.

Browse our comprehensive range of vaccine temperature monitoring devices below, divided into each area to help you find your ideal solution.

For more information about our vaccine data loggers or would like further advice about the best solution for your facility, get in touch with our friendly team at Loggershop. Call us on 01929 459459 or email [email protected].